Configurable, 3D printable carriage for small (up to 40 mm wide) aluminium extrusions. A 16Motion carriage consists of four 3D printed plates put together around the extrusion and some cheap, easily sourceable hardwares including 684 (4x9x4) bearings, M3 and M4 screws and nuts.

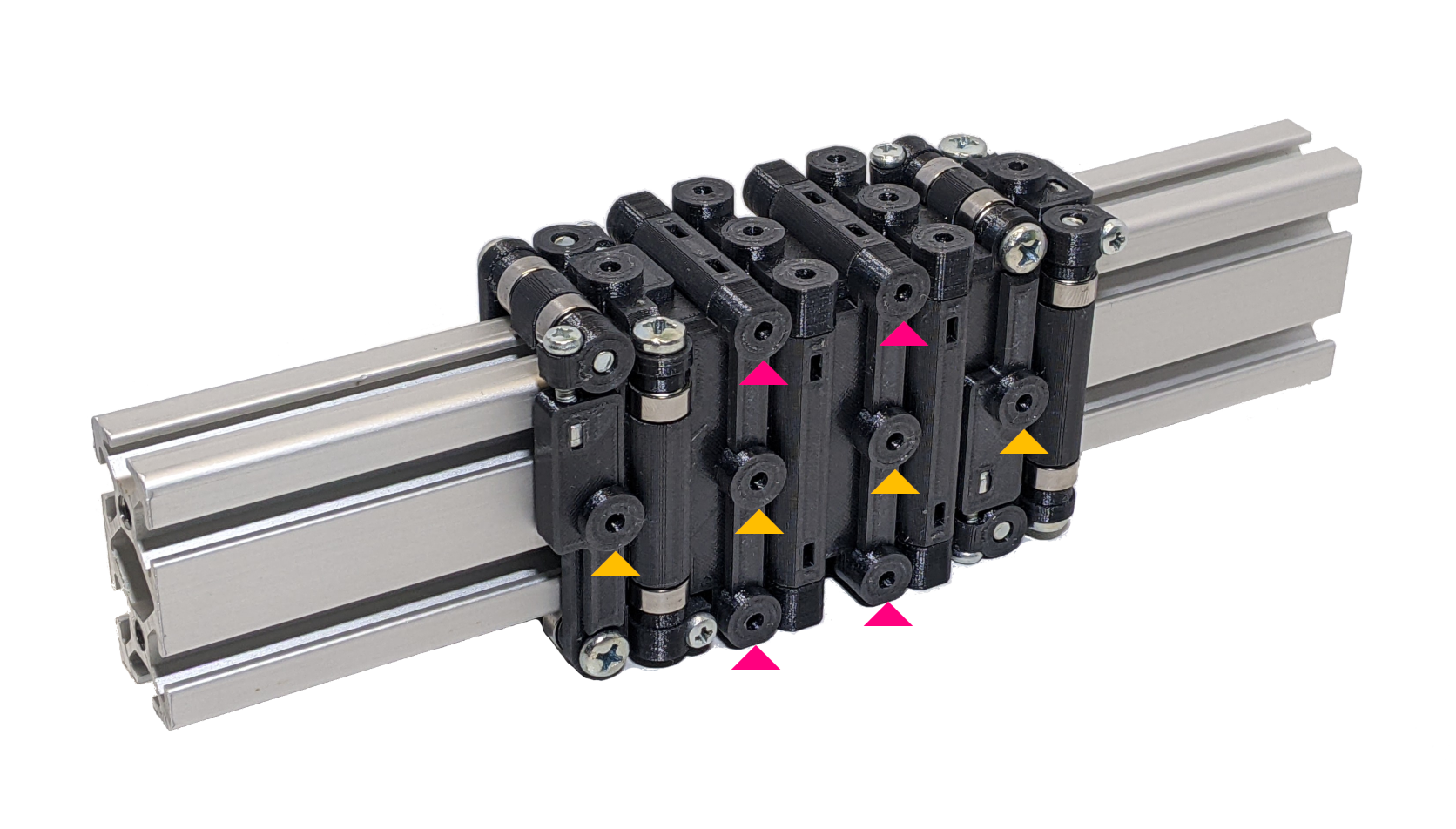

Each plate has eight attachment points to mount tools and accessories to the carriage using M3 screws and nuts. These eight points split up to two groups: four plate attachment points (indicated by yellow arrows) and four carriage attachment points (indicated by violet arrows).

Each plate has eight attachment points to mount tools and accessories to the carriage using M3 screws and nuts. These eight points split up to two groups: four plate attachment points (indicated by yellow arrows) and four carriage attachment points (indicated by violet arrows).

Carriage attachment points go through at least two plates, therefore they give additional stuctural rigidity to the carriage. If you use only plate attachment points, it is recommended to put an M3x16 screw into a few of the carriage attachment points as well. Horizontal distance between the points is fixed at 23 mm and the vertical can be calculated with this formula: vertical_distance = (extrusion_width + 9 mm) / 2

I'm not a professional mechanical engineer and haven't tested this design in a professional manner. I don't take any responsibilities for injuries and/or any damage caused by this design. Print and use it at you own risk!

As steel bearings are rolling on aluminium, they might leave marks and/or wear out the extrusion over time. For casual usage it's not significant, but for regular usage you should consider using lubrication (e.g. a thin layer of lithium grease should do the job).

If you can accept these conditions, then have fun building your carriages!

For one of the four plates you need:

- 3D printed plate x1

- 3D printer bearing spacer x4

- M4x(width of extrusion + 10 mm) screw x2 (e.g. if the extrusion is 20 mm width, screw length will be 20 mm + 10 mm = 30 mm)

- M3x16 screw x2

- M3 self-locking nut x2

- 684 bearing x4

I uploaded precompiled STLs to Thingiverse for 20 mm, 25 mm and 40 mm wide extrusions. Check them out HERE. If you can't find the suitable sizes to satisfy your needs, then proceed with the customization.

A few tips I picked up during development:

- The recommended material is PETG

- The plates require only touching buildplate kind of supports

- 1 mm wall thickness and 0.5 mm top and bottom thickness worked fine for me

You can find here the necessary steps for customizing the plates and assembling the carriage. Each step has a video tutorial at the end of it, don't forget to watch them on YouTube!

- Open FreeCAD and open Plate.FCStd

- If you see nothing but the model of a ring (spacer) you have to toggle the visibility of the plate. Right click on Plate object and select Appearance.... Then open the dropdown at Document window and select Flat Lines again

- Right click on the Plate document and check Skip recomputes

- Click on Spreadsheet and edit the Ideal extrusion width and Actual extrusion width parameters. Ideal extrusion width is the theoretical width of one side of the extrusion (e.g. 20 mm) and the Actual extrusion width is the measured size of it (e.g. 19.9 mm)

- Right click on Spreadsheet and select Recompute object

- Recompute all remaining objects as well (Plate, Spacer and Assets)

- Select Mesh from the Workbench selector

- Select Plate object by clicking on it and click on Create mesh from shape... button. My preferred settings for mesh creation are: Surface deviation => 0.1 mm and Angular deviation => 5.00 ˚

- Create mesh from the Spacer object as well

- Export meshes by right click on them and select Export mesh...

- After 3D printing, drill an M4 thread into the bottom left and top right holes

- Insert an M3 self locking nut into the socket below one of the preload levers

- Insert an M3x16 screw through the preload lever and drive it until it barely touches the lever

- Repeat the step above for the other lever

After you got your four plates printed and assembled, proceed with assemling the carriage. Additinal materials:

- 16 pcs of 3D printed spacers

- 16 pcs of 684 bearings

- 8 pcs of M4 screws with the length discussed in BOM for one plate section

Assembly:

- Put together the four plates. For this step it's nice to have long M3 screws or Allen wrenches poked through carriage attachment points

- Screw in one M4 screw into the threaded hole of a plate until it reaches the other side of the plate

- Put a spacer and a bearing in the route of the M4 screw

- Drive the screw until it can hold the spacer and the bearing

- Put an other pair of spacer and bearing in the route of the M4 screw and drive it all the way in

- Tighten the M4 screw firmly

- Repeat these steps for the remaining seven positions around the carriage

- Remove the things you used to hold the plates together

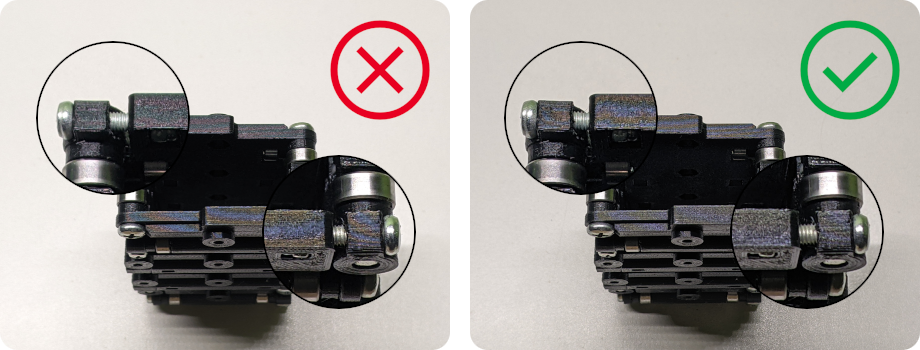

Here comes the tricky part. One rule: No play, no too much tension! Try to pay attention for having roughly the same tension for a pair of preload levers as you can see here:

My best practice to set the correct amount of preload:

- Get a piece of the extrusion the carriage was made for

- Sand down the edges on one end of the extrusion

- Slide the carriage onto the extrusion and place the extrusion on a flat surface vertically

- Start tightening the screws of one pair of the preload levers in small increments

- Check if you can feel any resistance when sliding off and on the carriage again

- Stop tightening the screws if you can feel a slight resistance when sliding the carriage onto the extrusion

- Repeat this process for the rest of the preload levers

Important notes:

- The carriage should fall through the extrusion by it's own weight when stands vertically. If it's stuck, you applied too much preload!

- It's completely normal if a few of the bearings are not rolling when the carriage is moving

- I hope the video describes the process well

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.