-

Notifications

You must be signed in to change notification settings - Fork 0

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

End Effector(Claw) #44

Comments

|

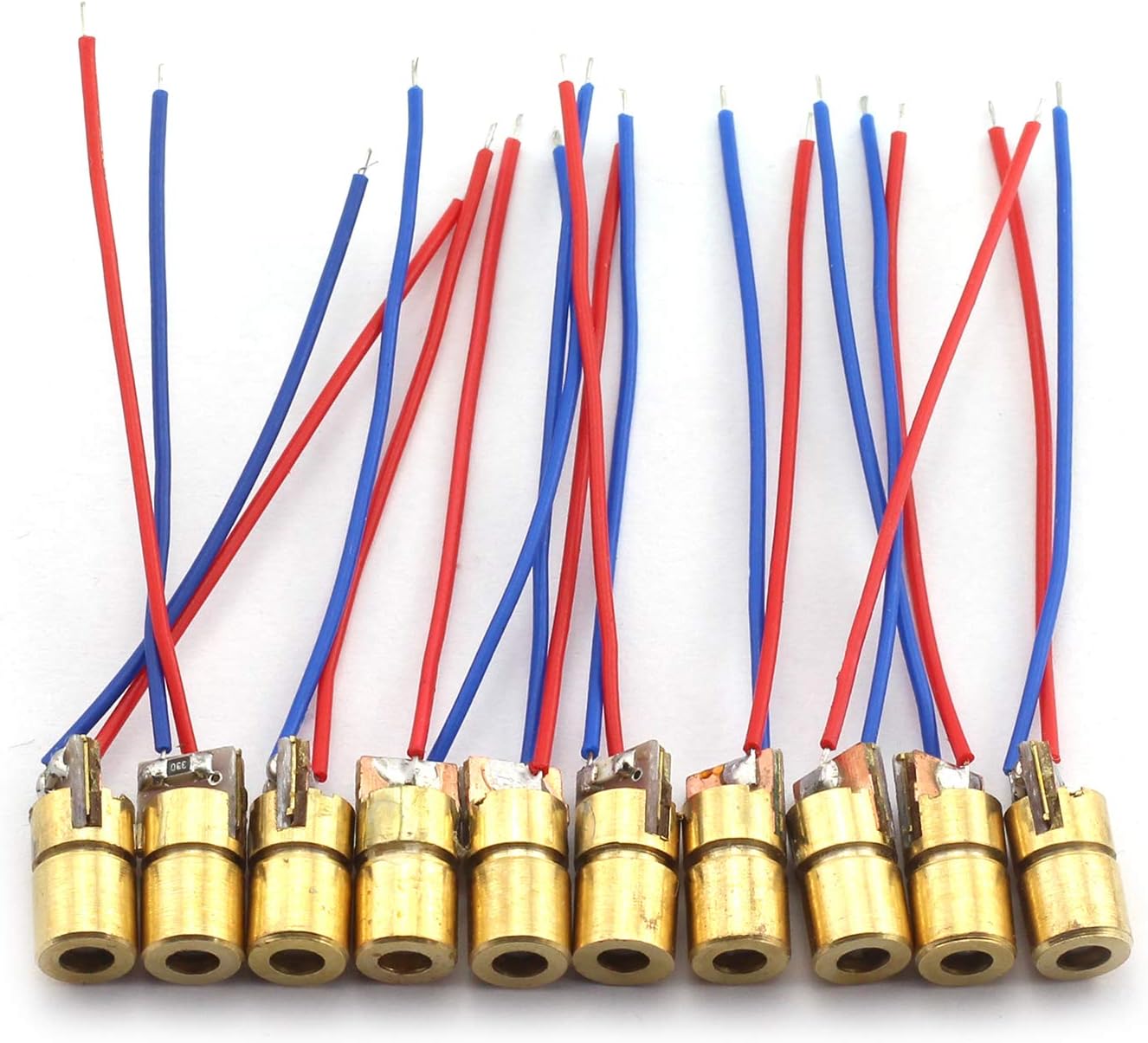

Laser pointer : https://a.co/d/f2Ml6A3 |

Current IssuesServo horn doesn’t fit Note: uses usb-c cable (can’t use a slip ring) |

Hardware List (in progress)

Electronics

|

Just kidding now this

|

7/15 UpdatePrinted & tested a laser cut/3D printed prototype Changes from the previous design

ConclusionsPros

Cons

Changes to make

|

|

Note that the accelerometer can be place on the wrist. Or if the differential wrist is used, you can put it on the feedback gear. The feedback gear is the gear on the back that looks like it doesn't do anything. The complexity of this design is that it needs a slip ring. Another option is what we did for the Rover Nessie (2nd rover) which was a board with a magnetic encoder (roll feedback) and accelerometer (pitch feedback) with a magnet on the feedback gear that can spin freely. |

|

@kammce got it, that's very good to know. |

|

I'm updating the 2024 end effector issue's opening comment to better reflect the new rules, so I'm putting the 2023 one here. DescriptionThe end effector is a 4 bar claw mechanism that will move small items (e.g. wrenches, hammers, etc.), transport rocks (>5 kg), and maneuver small items (e.g. type on a keyboard, tighten an allen wrench, flip switches, etc.). Goals/ConstraintsThe most relevant sections of the rules are as follows:

To summarize, the end effector will interact with the following:

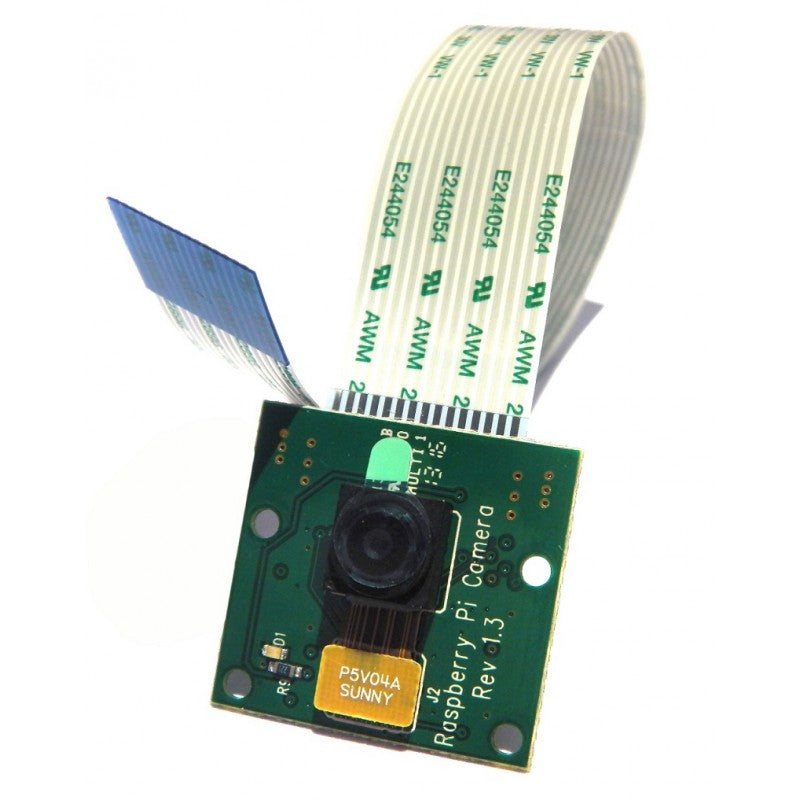

These are from the 2023 manual, but the guidelines shouldn't change much next year. This section will be updated when next year's manual is released Additional Contacts@starphys (mission controls) ElectronicsRaspberry Pi Zero ConnectionsCamera module --> raspberry pi via ribbon cable CADAccess CAD here |

Kate researched claws.

Stuff that needs to go on it: Claw, Motor, Hand Pcb(Check Slip Ring vs USB C cable), Laser pointer, whatever gears/mechanism.

The current design needs to be extended or redone to make more space.

The expected Degree of freedom(Pitch & Yaw range) needs to be discussed/ changed based on how the hand PCB is cabled.

This should be changed/finished on the 2023 rover, ideally before we start on the 2024 version so we can see what to change in the future.

The text was updated successfully, but these errors were encountered: